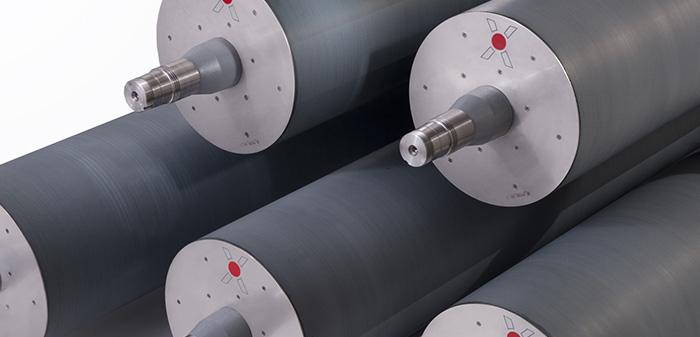

Roller bodies made by INOMETA

Rollers are the core component of many industrial applications, used for functions like transporting, pressing, smoothing, and coating. For over 40 years, INOMETA has been providing a wide range of standard and customized roller solutions, tailored to specific industry needs across various sectors like metal and plastics processing, printing, packaging, paper, and textiles. INOMETA relies on cutting-edge technologies and an innovative modular system with pre-fabricated components to ensure efficient and flexible production that matches your exact requirements.

Contact us today for your custom roller solution!

What is a roller body?

A roller body – typically made of aluminium, CFRP or GRP at INOMETA – forms the core of a roller. It’s responsible for the roller’s strength and durability, serving a variety of purposes depending on customer needs. Leading roller manufacturer INOMETA specializes in aluminium, fiberglass (GRP), and carbon fiber (CFRP) rollers. Their roller bodies are characterized by high strength, lightweight construction, and a long service life. State-of-the-art technologies and processes ensure high quality and safety. The company’s own modular system with pre-fabricated components guarantees competitiveness and short delivery times for customized roller bodies.

Focus on functionality – roller bodies from INOMETA

A roller consists of two main components: a central body and an outer coating or sleeve. The central body, often referred to as the core, provides the structural basis for the roller. Depending on its function, the coating can be referred to as a sleeve or simply as a coating and is used for force transmission or material transport. Both design and bearings are crucial to the functionality of INOMETA roller bodies. Three main types of rollers are used in the manufacturing process:

- Web Guide Roller with dead shaft

Web guide rollers with dead shaft are manufactured according to INOMETA’s modular system. They can be delivered with diameters between 30 mm and 360 mm. Depending on the application, roller lengths of up to 8,000 mm are available.

- Web Guide Roller with stub shafts

Web guide rollers with stub shafts are produced according to INOMETA’s modular system and can be delivered with diameters from 30 mm to more than 360 mm. Depending on the application, roller lengths of up to 8,000 mm are available.

- Web Guide Roller with journals

Web guide rollers with journals are produced according to INOMETA’s modular system and can be delivered with diameters from 30 mm to more than 360 mm. Depending on the application, roller lengths of up to 8,000 mm are available.

High-performance roller bodies made in Germany

At INOMETA, each roller body is designed according to the specific and technical requirements of the customer, guaranteeing optimum performance and maximum satisfaction. Comprehensive quality controls throughout the entire production process and INOMETA’s unique development expertise, along with a carefully considered value chain, contribute to innovative product solutions. The company employs state-of-the-art manufacturing, testing methods and technologies to ensure that every roller body complies with the highest quality standards – INOMETA customers benefit from durable, safe, and reliable solutions.

The roller manufacturer INOMETA is also characterized by the following:

- Unique development expertise in the field of aluminium rollers and GRP/CFRP rollers

- Mapping of the entire value chain in roller production, from aluminium or fiber composite tubes to high-performance rollers

- Innovative product solutions in roller production

- Many years of industry experience in roller production

- Process and quality monitoring through a certified ISO quality system

Broad selection with functional coatings

With its extensive range of roller types, INOMETA covers a broad spectrum of applications. From aluminium and CFRP/GRP tubes to finished rollers with functional coatings, we manufacture our entire product range, ensuring consistent quality and control.

CFRP high-performance rollers

Aluminium web guide rollers

Guide rollers

Breast rollers

Lay-on rollers

Sensor rollers

Anilox rollers

Heater rollers

Cantilever sensor rollers

Measurement rollers

Bubble collapsing rollers

Rubber rollers

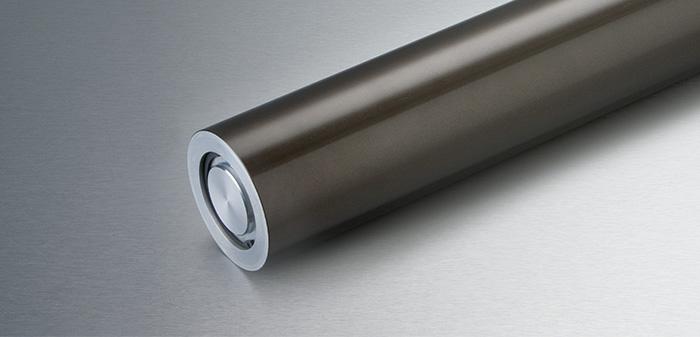

Aluminium roller bodies from INOMETA

Aluminium roller bodies are valued for their low weight, low inertia, and easy handling. This lightweight material is naturally corrosion-resistant and therefore ideal for humid environments. Additionally, aluminium’s excellent heat conductivity proves advantageous in specific applications.

CFRP roller bodies from INOMETA

CFRP roller bodies offer an excellent strength-to-weight ratio for exceptional performance. Due to their inherent rigidity, they are ideal for applications that require precision and stability. In addition, their corrosion resistance makes them ideal for high-precision manufacturing processes that require precise movements with minimal vibrations.

INOMETA, a leading roller manufacturer, delivers custom CFRP/GRP roller bodies for various applications across industries like metal processing, papermaking, textiles, and plastics.

Joining techniques for roller bodies – focus on precision

Joining components is a crucial step in roller body manufacturing, demanding highest precision. At INOMETA, the production of the roller bodies goes through several steps to ensure the desired shape, surface quality and precision. The leading manufacturer employs a variety of joining and machining techniques to deliver high-precision, high-quality customized roller bodies.

INOMETA utilizes established methods like joining, pressing, gluing, and bolting to create strong and durable joints on roller bodies of any size, ensuring structural integrity, reliability, and performance. Precision machining processes such as turning, milling and grinding are used to shape the outer form of the roller bodies. This guarantees exact dimensions, functionality, and surface quality, as well as improved service life and efficiency – meeting both technical specifications and individual needs.

The right roller body coating for individual requirements

INOMETA has made a name for itself as an expert in functional roller surfaces and, thanks to its extensive know-how in the field of processing and finishing techniques, offers customized solutions that exceed the requirements of various industries. The company uses a precise quality management system to guarantee the required aesthetic, haptic and functional properties of the roller surfaces.

INOMETA’s functional surface coatings are known for their precision and versatility, seamlessly tailored to customers’ applications and requirements. This enables the company not only to meet the latest quality standards, but also to impress with innovative solutions for optimizing the efficiency and performance of rollers.

Comprehensive roller service – modernization, repair & recoating

INOMETA’s comprehensive roller services includes a variety of measures to revitalize the performance of your rollers – from coatings and mechanical repairs to on-site troubleshooting:

- On-site roller inspection

- Roller modernization, repair and recoating of rollers made of CFRP, aluminium or steel

- Development of customized maintenance plans

- Dynamic balancing in accordance with VDI 2060, ISO 1940

- Journal crack testing using ultrasound and magnetic particle methods, journal repair or replacement

- Customer-related and application-related development of thermal coatings and composite coatings

- Service of single tube spreader rollers (Bowmaster and X-BOW)

- Laminate testing and repair of CFRP rollers

- Assembly and disassembly of add-on parts such as sheaves and roller bearing housings

- Journal repair or replacement

- Dynamic balancing in 2-5 planes in accordance with VDI 2060, ISO 1940

- Extensive testing before delivery

- Bearing condition analysis

- Predictable costs and delivery times thanks to standardized repair processes

- Transport organization with advance appointment reservation

Turning and grinding machining extends to components with dimensions of 1.4m in diameter, 15m in length and 20 tons in weight. The coating of components with dimensions of up to 2 m in diameter, 17 m in length and 20 t in weight is also part of INOMETA’s range of services.

Innovation through experience – shaping the future together with INOMETA

INOMETA is your trusted partner for high-performance rollers, pushing the boundaries of quality, precision, and innovation. From customized roller bodies to state-of-the-art surface solutions, the company enables efficiency improvements in various industries and raises roller performance to a new level.

Contact INOMETA today to discuss your unique roller needs and shape the future of your production with innovative solutions.