Using the right roller and the right sleeve you sustainably increase print quality and save process costs.

Maximum print quality

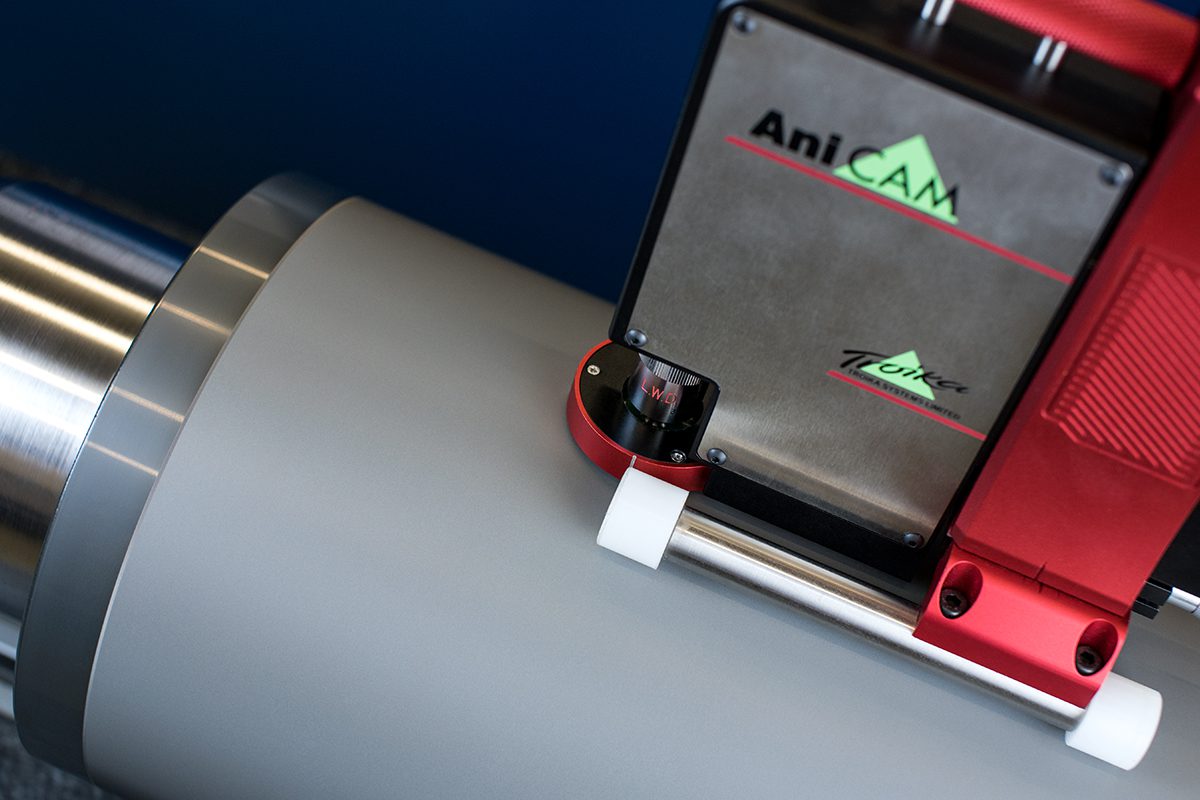

Easily reaching ideal print results and developing them sustainably using the INOlox® anilox rollers and INOlox® anilox sleeves. Higher print quality with optimised ink release can be achieved by the adjusted ratio of volume and cell depth. Improved lying behaviour in the surface and a concise edge sharpness provide brilliant print images with strong tonal values.

Highest quality at low cost

The entire process costs can be decreased by the use of our high-quality products, the INOlox® anilox rollers and sleeves. You profit from low maintenance requirements an excellent cleaning behaviour and durable roller and sleeve base cores.

Consultation and service

We use a detailed process analysis on site to find out which anilox roller is right for you printing process. Already during your configuration of your anilox roller we support you with our advice to find the right product for your specific application. Further we use specific printing tests in the ongoing process to analyse and optimise faulty ink releases and to improve print quality. All of our repair and service work is subject to longterm logging and archiving.

We maintain high service standards

- Help selecting the right roller setup

- On-site volume measurement

- We select the right cleaning process together

- Process optimisation

- Support selecting fitting accessories

Application-related INOcell® engraving types

The heart of our INOlox® anilox rollers are the high-quality engravings. Every single INOcell® engraving type features different specifications and is developed in accordance with the respective application. INOMETA has six anilox roller engravings.

Highest precision in every detail

Right after the laser engraving, the anilox rollers and sleeves receive a specific polishback tailored to the application. This finish allows outstanding print results with reduced score line formation. The INOMETA manufacturing processes enable the production of consistent cells.

Strong quality. Strong reasoning.

We make precision products of the highest quality down the smallest detail.

There are good reasons for INOMETA anilox roller products:

- Great cleaning behaviours owing to the flat and uniform cells

- Minimal doctor blade wear and score line formation owing to the INOcell® polishing standard

- Increased colour density with the same volume in contrast to hexagonal engravings using Elongated Cell

- Very consistent coating system with little dot gain through INOcell® engraving technology

- Highest repetitive accuracy

We would be very happy to advise you on site and check the use of our rollers for your application situation.

Further information about anilox rollers and sleeves

Here you find further information about INOlox® anilox rollers and INOlox® anilox sleeves.

Products

About INOMETA

About AVANCO