With one of the largest investments in the company’s history, INOMETA has significantly expanded its roller production at its Herford site. The specialist for support bars, adapters, and rollers made of aluminum and CFRP relies on highly automated processes to sustainably increase efficiency, quality, and competitiveness – and secure further growth.

At the beginning of May, the company presented the new, fully automated production line to customers, partners, and leading representatives from the coating and converting and battery manufacturing sectors as part of a two-day event.

Fully automated production, increased competitiveness

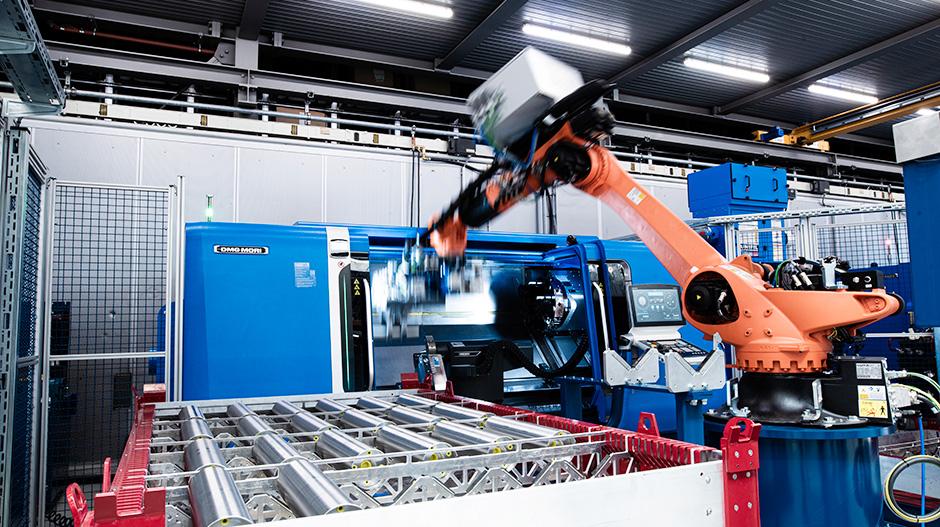

At the heart of the expansion, in which INOMETA has invested several million euros and which represents one of the largest investments in the company’s history, are four new production cells in which rollers up to two meters long and with variable diameters are processed. Each cell is equipped with an industrial robot.

To create the necessary space for the expansion, a production area in the immediate vicinity of the main building was relocated to a newly rented building. This allowed the expanded roll production to be integrated without the need for additional hall construction. At the same time, an automated pallet warehouse was built.

INOMETA Managing Director Christof Schotten: “In addition to training our own junior staff, automation is the second pillar with which we want to counteract the shortage of skilled workers and secure our production and delivery capacity.”

INOMETA Managing Director Christof Schotten: “In addition to training our own junior staff, automation is the second pillar with which we want to counteract the shortage of skilled workers and secure our production and delivery capacity.”

Innovation live, the coatings and coatings community meets in Herford: INOMETA celebrated the opening of a new, state-of-the-art production cell for the automated manufacture of high-quality rolls. The motto: The next technological advancement in roll construction.

Innovation live, the coatings and coatings community meets in Herford: INOMETA celebrated the opening of a new, state-of-the-art production cell for the automated manufacture of high-quality rolls. The motto: The next technological advancement in roll construction.

With the expansion, INOMETA is increasing its production capacity in roll manufacturing. At the same time, production and delivery times are significantly shortened, flexibility increased, quality improved, and scrap rates reduced, explains Managing Director Christof Schotten. The automation of the system enables consistent, highly flexible production in high volumes.

With the plant’s high level of automation, INOMETA aims to strengthen its competitiveness and counteract demographic change. “In addition to training our own junior staff, automation is the second pillar we use to counteract the shortage of skilled workers and secure our production and delivery capabilities,” says Christof Schotten.

During a tour of the production facility, participants were able to see the automated production cells in action.

During a tour of the production facility, participants were able to see the automated production cells in action.

With the expansion, INOMETA is significantly increasing its production capacity in roller manufacturing.

With the expansion, INOMETA is significantly increasing its production capacity in roller manufacturing.

High-profile Conference in Herford

To mark the opening of the new production area, INOMETA hosted a two-day conference in Herford, attended by over 40 guests from the coating and converting industries, including flexographic printing, as well as from the battery and automotive industries. The motto of the invitation: “Celebrate the next technological milestone in roller construction with us.”

A highlight of the conference on the second day at the company headquarters was the keynote speech by Prof. Michael ten Hompel on the topic “Thinking it through – A look at the future of industrial AI.” Ten Hompel highlighted the opportunities and challenges presented by the increasing use of artificial intelligence in industry. He impressively described how AI-based systems can already deliver surprising and sometimes unexpected results – an aspect that both fascinated and provoked thought among the audience.

Finally, the participants were given a tour of the production facility, where they could see the automated production cells already in operation. INOid, the new INOMETA product for digital roll management, was also presented, which also aroused keen interest among the visitors.

Interview with INOMETA Managing Director Christof Schotten

Produkte

Über INOMETA

Über AVANCO